Integrated Production Technologies | AC Pathway

SREB Advanced Career|Integrated Production Technologies

Integrated Production Technologies AC Pathway

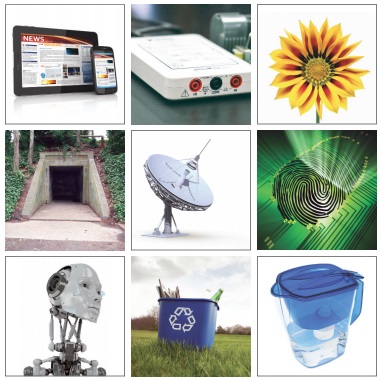

Advanced Career’s STEM curriculum — Integrated Production Technologies — engages students in using innovative industrydriven technologies to imagine and design new and improved products. Great entry-level jobs leading to challenging, high-paying careers are available across the nation for students who have the academic and technical knowledge and skill sets to succeed. Students also need creativity and problem-solving abilities to coordinate information and analyze data. With these skill sets, students will be prepared to dream, build and maintain cyber-mechanical systems; invent unmanned exploration vehicles; apply electrical and mechanical engineering principles to the construction of production systems; and use logistics to develop solutions to the modern world’s most pressing needs and wants.

This four-course AC sequence will allow students to apply what they learn in physics, chemistry and biology to real-world projects using emerging, cutting-edge materials. Students will work on the frontiers of product development by applying nanotechnology to new areas of need.

Students will reengineer existing products to reduce the energy and material costs required to produce them, invent new products, and create more durable and efficient products using automated computer-aided design and manufacturing programs. Across the curriculum, working in teams and in online communities with industry professionals, they will learn by applying engineering design processes to authentic project-based assignments. Students will also engage in 3-D computer-aided design, documentation, prototyping, testing and analysis. Students will also design modern production systems, create energy efficient work cells and explore robotics with the programmable logic controllers and computer numerical control systems used in the world’s leading industries.

The curriculum also incorporates the lean management tools and techniques used by leading industries to improve their processes, increase the quality of their products and make them more competitive. Students will use advanced measurement tools to gather quality control data and apply principles from Six Sigma, lean manufacturing, statistical process control, total quality management and inventory control to design just-in-time production systems.

Students completing the program may become a National Instruments’ Certified LabVIEW Associate Developer (CLAD) and may be prepared for earning other relevant industry certifications

The Four Courses of Integrated Production Technologies

Integrated Production Technologies will appeal to students who want to work with cutting-edge materials, using their knowledge of physical and biological sciences, to create products emerging from new advanced technologies in cost-effective ways.

| Course 1: Advanced Technology for Design and Production | This course will engage students in the use of modern technologies in the design and improvement of products. Students will use three-dimensional CAD software in the creation and analysis process. Students will document designs using standards set by industry for design documentation. Students will implement methods of green production and just-in-time component supply which allow for the lowest cost and highest quality products. Students will design and troubleshoot data acquisition, programmable logic control, process monitoring, automation and robotic systems. Students will incorporate sensing and vision systems, utilizing cameras and sensors to control automated systems. |

| Course 2: Systems of Advanced Technology | In this course, students will apply the technologies that are found in modern clean, production environments. Students study effective and energy efficient control of pumping, conveyors, piping, pneumatic and hydraulic control systems. Students apply total quality management to production design to assure quality. Students also focus on properties of materials and material testing, creating documentation to support designs, examining properties and justifying material selections based on properties. Students learn that old products become the new raw materials for new products. |

| Course 3: Mechatronic Systems for Advanced Production | Students will design cost-effective work cells incorporating automation and robotics to improve quality of final products. The advanced production in this course depends on the use and coordination of information, automation, network systems, vision and sensing systems. Students will design and create mechatronic systems and automated tooling to accomplish these advanced tasks. Students produce authentic documentation about their cyber-mechanical systems and the integration with data to control and monitor processes. |

| Course 4: Design for the Production of Advanced Products | Students will create plant designs to process and automatically assemble materials into new products. Students follow the process of developing and producing a new product from prototype to final product. They will accomplish this by creating a production flow plan that allows for the mass production of the product. Students will analyze and evaluate all aspects of the design and production processes with an emphasis on clean, lean and green production. Students will utilize data acquisition, quality control processes and Six Sigma methodology to control production. |

Fully Developed Pathway Programs

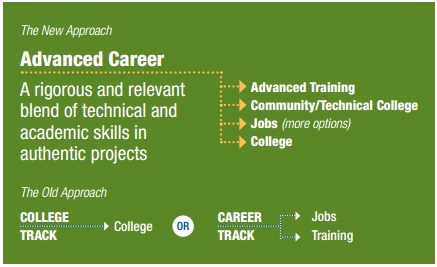

Advanced Career (AC) encompasses a coherent sequence of four ready-to-implement courses; comprehensive training for teachers; access to tools and technology for project-based learning; and end-of-course assessments. To ensure fidelity from site to site, each course has a syllabus that includes instructional philosophy, instructional delivery and support systems, assessment and a recommended grading system.

*Content and images provided by SREB.org/AC

*Content and images provided by SREB.org/AC