Hello all! It’s been awhile since we’ve posted about fischertechnik, so let me pick up where we left off in November. Last time around I was telling you about the students learning STEM at Westfield Vocational Technical High School in MA, and how they were beginning their first hands-on project using the fischertechnik STEM Lab Program. As I mentioned previously, this project involved creating a braking system, such as you would find on a racing bicycle. Today I want to share some photos that show some of the ways the students approached this design problem.

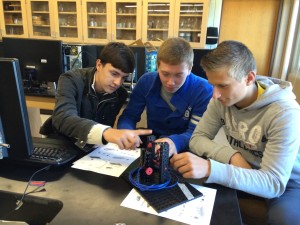

Once again, the core idea behind the fischertechnik STEM Lab Program is that it is hands-on, project based learning. Students are taught the fundamental concepts they will need to address a problem, and provided with the tools they can use to research and design an answer. How they actually solve this problem (or fail to) will be totally dependent upon what they do…i.e., their efforts, research and creativity. Working in small groups, they will have to decide on what type of solution they want to use, come up with a design, do the trial and error, the documentation and so on, and eventually present a working prototype.

Once again, the core idea behind the fischertechnik STEM Lab Program is that it is hands-on, project based learning. Students are taught the fundamental concepts they will need to address a problem, and provided with the tools they can use to research and design an answer. How they actually solve this problem (or fail to) will be totally dependent upon what they do…i.e., their efforts, research and creativity. Working in small groups, they will have to decide on what type of solution they want to use, come up with a design, do the trial and error, the documentation and so on, and eventually present a working prototype.

Some of the students will devise solutions that are stripped down and simple, others will design solutions that are quite elaborate. Some will function smoothly, others might require refinement. Many of these prototypes may share similarities, but ideally each group should come up with an answer to the design problem that exhibits unique characteristics, with no two models being exactly the same. This really brings student engagement toward learning STEM concepts.

As you will note, all of the examples shown on this page utilize pneumatic cylinders, and of course a wheel which the braking system is to stop. Some of the prototypes use only one cylinder, others as many as four. Some are quite stable, making use of aluminum struts for added strength. Others place more of an emphasis on an economy of design. Ultimately, all of this will take a back seat to the simple matter of whether or not the prototype can effectively and reliably perform its intended function.

Students Using fischertechnik STEM Lab Program

Besides designing the models, students also had to provide brief reports telling how they approached the project, or dealt with setbacks that occurred. Here is one example, written by Josh and Dylan in Group 5, which provides an outline of their process:

Define the problem: The problem was that the customer needed a new bike braking system for their new racing bikes.

Define the problem: The problem was that the customer needed a new bike braking system for their new racing bikes.

Research the problem: We read the report on our task to redesign a braking system and searched different designs on the Internet.

Develop possible solutions: We created some designs with all of the best pros and the least cons and built it with our kits. It was a simple, durable design using the least amount of parts. Therefore the less parts, the less problems.

Choose the best solution: The best solution was a design similar to a car braking system, it uses one piston on the side to stop the kinetic energy from the objects movement. In the testing it proved more effective than the regular braking system which uses a caliper that compresses both sides. In our design the pads have a longer life expectancy.

Create a mock up: Our mock up creation didn’t take long since we already had the plans memorized. When we created our mock up we used the best features and design methods. Our mock up in the end, to us, performed better than we had hoped. It had one design flaw, the wheel that connects to the column fell out when the braking piston pushes against it.

Test and evaluate: The prototype works very well except when we push the brake piston down. We could improve this by putting a stopper on the wheel axle, thus holding the wheel from falling out.

Redesign: We can further improve this design by putting a stopper on the axle. We could also improve this by adding more pistons.

One group of students mentioned that if given time, they would have wanted to try to incorporate an electronic element to make their braking system more efficient. Another group described the trial and error process involved with working with pneumatics for the first time, and that getting the brake to engage was only half the process, that it was also just as important to make in disengage. And as this was their first real experience building with fischertechnik without detailed instructions provided, some mentioned that it took a little time to get used to the way the building system worked. As Roman, Alex and Konstantin in Group 17 wrote in their report:

One group of students mentioned that if given time, they would have wanted to try to incorporate an electronic element to make their braking system more efficient. Another group described the trial and error process involved with working with pneumatics for the first time, and that getting the brake to engage was only half the process, that it was also just as important to make in disengage. And as this was their first real experience building with fischertechnik without detailed instructions provided, some mentioned that it took a little time to get used to the way the building system worked. As Roman, Alex and Konstantin in Group 17 wrote in their report:

“When we started working together we had some complications making the brake system because we weren’t familiar with fischertechnik. … (but) after about 3 days of work we got more familiar by testing it out and we were able to improve the brake system design. The team I was working with worked well, and we put together out Ideas to improve it. In all it was a successful project and we loved making it.”

In part two, I’ll share some video of the prototype models created for this initial project. Meanwhile, if you’d like to know more about the fischertechnik STEM Lab Program, we invite you to register now for our next webinar presentation on February 20th.

So until next time, happy building!

Author: Lance Zurek

Share this Post