As manufacturing continues to push towards digitization, businesses are realizing a need to educate their workforce. They want to prepare workers and make these new concepts relatable to them with realistic and engaging training. This is where fischertechnik fits in perfectly. Designed to serve this need, the fischertechnik Training Factory Industry 4.0 simulation model allows digitization activities to be simulated, learned, and applied on a small scale before they are implemented on a larger scale.

Demonstrating Digitization with fischertechnik

Training Factory Industry 4.0 is designed specifically for demonstrating and teaching cloud-based monitoring and control. This tabletop-sized model illustrates the processes in a digitized smart factory. The simulation starts with the ordering and delivery of raw materials, goes through the production and quality control processes, and takes you all the way to the delivery of finished products. It helps address the need for stronger networking and more relevant information on all production levels.

Training Factory Industry 4.0 is designed specifically for demonstrating and teaching cloud-based monitoring and control. This tabletop-sized model illustrates the processes in a digitized smart factory. The simulation starts with the ordering and delivery of raw materials, goes through the production and quality control processes, and takes you all the way to the delivery of finished products. It helps address the need for stronger networking and more relevant information on all production levels.

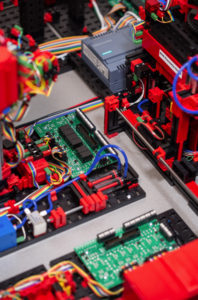

This model includes four individual workstations that work together as a self-contained, material cycle. These workstations are a vacuum gripper robot, a high-bay storage warehouse, a multi-processing station with oven, and a sorting line with color detection. Controlled and monitored from a special cloud-based dashboard this integrated model allows for the display of three different perspectives including a customer view, a supplier view, and a production view.

This model includes four individual workstations that work together as a self-contained, material cycle. These workstations are a vacuum gripper robot, a high-bay storage warehouse, a multi-processing station with oven, and a sorting line with color detection. Controlled and monitored from a special cloud-based dashboard this integrated model allows for the display of three different perspectives including a customer view, a supplier view, and a production view.

Environmental data from the factory such as temperature, air quality, and humidity can be tracked on the dashboard. A camera attachment allows for visual monitoring of the factory on the dashboard. With the help of NFC chips and an RFID reader, data for individual workpieces in the production cycle can also be tracked. This model is available in 9V and 24V versions.

Training Factory Industry 4.0 24V

The most recent release is the 24V version. The Training Factory Industry 4.0 24V is controlled by a PLC (not included) and offers a ready-made sample program (as Structured Text, ST) that is based on a Siemens S7-1500. Newly developed 24V adapter boards that come pre-assembled interface with the PLC via terminals. This latest generation of adaptor boards allows your encoder motors to be controlled in speed via PWM and for the use of push/pull output stages for phototransistors and buttons.

You can connect the 24V model to the fischertechnik cloud. This is made possible with a fischertechnik TXT controller that is supplied with power via the adapter board. The TXT controller also communicates in MQTT to the IoT gateway (Raspberry Pi) which in turn translates in OPC-UA to the PLC controller. This also allows the 9V based components on this model—such as the environmental sensor, the USB camera, the brightness sensor, and the NFC reader– to communicate via the MQTT interface and read out from the PLC. There is also the possibility of an optional connection to a separate cloud offering maximum flexibility for the end user.

You can connect the 24V model to the fischertechnik cloud. This is made possible with a fischertechnik TXT controller that is supplied with power via the adapter board. The TXT controller also communicates in MQTT to the IoT gateway (Raspberry Pi) which in turn translates in OPC-UA to the PLC controller. This also allows the 9V based components on this model—such as the environmental sensor, the USB camera, the brightness sensor, and the NFC reader– to communicate via the MQTT interface and read out from the PLC. There is also the possibility of an optional connection to a separate cloud offering maximum flexibility for the end user.

As mentioned above, the PLC sample program for controlling the fischertechnik Training Factory Industry 4.0 was created for use with a Siemens S7-1500. It is available free of charge at GitHub. You can also use the Training Factory Industry 4.0 with many other popular PLC models and brands, and individual solutions can be programmed and implemented by the end-user (it may be necessary to make small adjustments to the sample program, which are to be implemented independently.) If you have any questions or would like to learn more, please contact Studica.

Moving Forward

Truthfully, this article just covers the tip of the iceberg when it comes to this powerful simulation model and how it can demonstrate digitization in the production process. There is much more to cover, so if you would like more information or to request a brochure, please contact Studica. We have a webinar coming up, “Exploring Automation & Control Systems with fischertechnik” that will delve deeper into this model and others in the fischertechnik line of simulation solutions. The webinar is scheduled for Thursday, November 19th at 3PM Eastern – Register Now if you are interested. If that time doesn’t work for you, you can view a previously recorded webinar here.

Share this Post