For years we’ve all been hearing a lot of talk about IoT, but for many of us, it really seemed like just that…a lot of talk. But while we may have still been scratching our heads about what exactly it is, and why it’s important, it’s been growing exponentially.

What exactly is IoT?

For the uninitiated, IoT is an acronym, the letters of which stand for “Internet of Things”. If we look to Wikipedia, they define it as “a system of interrelated computing devices, mechanical and digital machines provided with unique identifiers (UIDs) and the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction.” More simply put, it’s being able to control and monitor machines and processes remotely.

Where do we find the Internet of Things?

If you know someone who turns on the lights and other appliances in their home via an app on a phone, that’s an example of IoT. But IoT isn’t just about trendy convenience. IoT is used in the medical field for data collection, remote monitoring of blood pressure and heart rates, and emergency notification systems. IoT is used in the transportation field for traffic control, logistics, and even actual vehicle control. In the construction field, new buildings are now designed to be “smart”, including energy management systems for increased efficiency. And in industry and manufacturing, IoT is allowing companies to better manage assets, and optimize production and supply chain networks. And these are only a few examples.

How fast is IoT growing? And what is the connection to 5G networking?

You’ve probably read about the importance of upgrading to 5G networks, and it’s not just about having our smart phones load websites faster, it’s about IoT. While there are still debates about the potential trade offs of such an upgrade (such as the costs in both dollars and possible health risks), the increasing move towards IoT will likely be the engine that moves 5G forward. Per an article titled “The Future of IoT: 4 Predictions about the Internet of Things” posted October 7, 2019 on the Thrive Global website, it is expected that in the coming ten years, IoT devices will grow to anywhere from 75 billion to over 100 billion, and the move to 5G networking is deemed essential for this to occur. To quote: “Today’s 4G network can support up to 5500 to 600 NB(Narrowband)-IoT devices on a single cell. With a 5G network, up to one million devices can be handled by a single cell.” The same article also predicts that between now and the year 2025, IoT will have an astounding compound annual growth rate of 28.7%!

Investment site McKinsey & Company posted an article titled “Growing opportunities in the Internet of Things”, which stated to their readers that it’s no longer just hype, and that IoT was quickly crossing over into mainstream business use. They estimated the number of businesses utilizing IoT to have increased from around 13% back in 2014 to about 25% at the time of their article (July 2019), and they also projected a worldwide increase of IoT projected devices to about 43 billion by 2023, which would be an almost threefold increase from 2018.

IoT and Education

In education, the move towards utilizing IoT received an unexpected push this Spring, with the closure of schools across the world in observance of social distancing guidelines brought on by the spread of Covid-19. This dramatic new situation necessitated that educators begin to explore new ways of teaching, such as remote learning. While in most cases this resulted in things like Skype or Zoom based sessions, the future is clearly in implementing more elaborate tools and systems for monitoring and guiding students via the internet and the cloud.

In short, if you’re not already using IoT in some way, you will be very soon. And if you’re involved in preparing students with the skills employers will require when they enter the job market, you’ll need tools that help them to not only understand what IoT is, but more importantly, to understand HOW it works.

That’s where fischertechnik can help.

Understanding the Smart Home with fischertechnik—the Robotics Sensor Station IoT

A professional introduction to data logging. This set enables students to build a progression of engaging and instructional models to experiment with and understand different aspects of instrumentation and cloud-based control as is found in a smart home setting. Includes everything needed—controller, software, and power supply—for building six models. Also includes access to free downloadable instructional activity materials to provide guidance on different experiments to be performed with each model. For use in middle and high school settings. Shop Now

A professional introduction to data logging. This set enables students to build a progression of engaging and instructional models to experiment with and understand different aspects of instrumentation and cloud-based control as is found in a smart home setting. Includes everything needed—controller, software, and power supply—for building six models. Also includes access to free downloadable instructional activity materials to provide guidance on different experiments to be performed with each model. For use in middle and high school settings. Shop Now

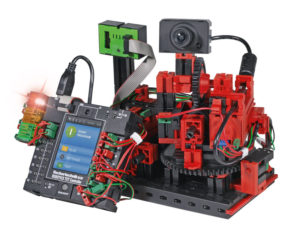

Explore cloud-based automation & control with fischertechnik Training Factory Industry 4.0

Changes in industrial production driven by digitalization make stronger networking and more relevant information necessary on all production levels. With the fischertechnik Training Factory Industry 4.0, these digitalization activities can be simulated, learned, and applied on a small scale before they are implemented on a large scale. This unique model is ideal for exploring and understanding industry 4.0 applications in vocational schools and training as well as for research, teaching and development at universities, in companies and IT departments. The simulation depicts the ordering process, the production process and the delivery process in digitized and networked process steps.

The following topics can be implemented with fischertechnik Training Factory Industry 4.0:

Training and simulation on a realistic production model

Training and simulation on a realistic production model- In-depth learning through haptic comprehension

- Optical and sensory applications

- Digital traceability with NFC/RFID

- Customized production in lot size 1

- Integrated cloud connection, control via smart devices

- Using and operating dashboards

- Web-based remote maintenance

- Linking of production and materials planning data

- Connection of upstream and downstream logistics processes

- For experts: own program creation in C/C++ Shop Now

To find out more about the fischertechnik Sensor Station IoT, the Training Factory Industry 4.0, or any of the other fischertechnik Simulation Solutions, please contact Studica directly.

Article Written By:

Lance Zurek, Product Manager, fischertechnik Education Division at Studica, Inc.

Share this Post