Products tagged with 'gripper'

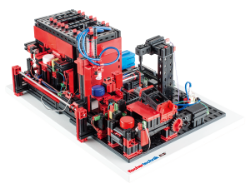

fischertechnik Multi-Processing Station with Oven 24V

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Multi-Processing Station with Oven 9V

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Pre-assembled training model, wired to 2 fully programmed fischertechnik ROBOTICS TXT Controllers.

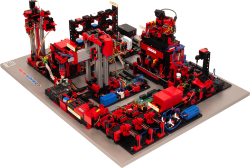

Training Factory Industry 4.0 | 24V

The Training Factory Industry 4.0 – 24V from fischertechnik is an extremely flexible, modular, reasonably priced, and highly robust training and simulation model for use with most popular industrial PLCs. Explore Industry 4.0 and more with this powerful 24V simulation model that includes a variety of factory modules. Details below.

fischertechnik Training Factory Industry 4.0 - 9V

The fischertechnik Training Factory Industry 4.0 is extremely flexible, modular, reasonably priced, and highly robust training and simulation model.

Changes in industrial production driven by digitalization make stronger networking and more relevant information necessary on all production levels. With the fischertechnik Training Factory Industry 4.0, these digitalization activities can be simulated, learned, and applied on a small scale before they are implemented on a large scale.

The fischertechnik Training Factory Industry 4.0 is a 9V simulation model that consists of factory modules including storage and retrieval stations, a Vacuum Gripper robot, High-Bay Warehouse, Multi-Processing Station with Oven, a Sorting Line with Color Detection, an environmental sensor, and a pivoting camera. It is especially designed for exploring and understanding industry 4.0 applications in vocational schools and training as well as for research, teaching and development at universities, in companies, and IT departments.