Products tagged with 'txt controller'

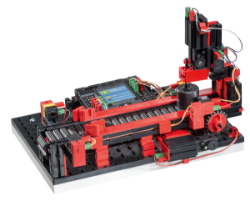

fischertechnik Indexed Line with 2 Machining Stations 9V

U-shaped conveyor line. Features a milling and a drilling station, and four conveyor belt sections. Fully assembled training model, wired to two pre-programmed fischertechnik ROBOTICS TXT Controllers.

fischertechnik Multi-Processing Station with Oven 9V

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Pre-assembled training model, wired to 2 fully programmed fischertechnik ROBOTICS TXT Controllers.

fischertechnik Punching Machine with Conveyor Belt 9V

Conveyor belt with two light barriers, one machining station, and one workpiece. Designed to simulate the movement and punching of workpieces on an automated line. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

fischertechnik Sorting Line with Color Detection 9V

System for detecting workpieces of different colors and sorting them via a conveyor belt into three different storage bins. Fully assembled training model, wired to pre-programmed fischertechnik ROBOTICS TXT Controller.

- 1

- 2