Products tagged with 'high bay warehouse'

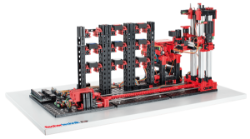

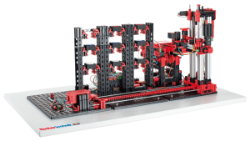

fischertechnik Automated High Bay Warehouse 24V

Transfer station with conveyor belt, with shelf stacker for storing and retrieving special workpiece carriers, and 9 storage spots. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Automated High Bay Warehouse 9V

Transfer station with conveyor belt, with shelf stacker for storing and retrieving special workpiece carriers, and 9 storage spots. Fully assembled training model, wired to pre-programmed fischertechnik ROBOTICS TXT Controller.

fischertechnik Factory Simulation 24V

The fischertechnik Factory Simulation model combines four models --Vacuum Gripper Robot, Automated High Bay Warehouse, Multi-Processing Station with Oven, and the Sorting Line with Color Detection--into one self-contained material cycle.

Workpieces are retrieved from the Automated High Bay Warehouse using the Vacuum Gripper Robot, and then moved to the Multi-Processing Station with Oven. After the work-piece has been processed by this machine, it is then sorted by color in the Sorting Line with Color Detection, before being again moved by the Vacuum Gripper Robot to the Automated High Bay Warehouse for storage. This fully assembled factory simulation training model is ideal for use with PLCs (Programable Logic Controllers) and PLC programming software.