Build Guide: How to Build a Chassis with the FTC Drive Base Kit

These build instructions will walk you through building your Mecanum Drivetrain. (Also referred to as a Mecanum Chassis or Mecanum Drive Base). The FTC Drive Base Kit – v2 from Studica Robotics includes the parts needed to complete this build.

Download the Drive Base Kit v2 D-Shaft Build Guide as a PDF

Download the Drive Base Kit v2 Hex-Shaft Build Guide as a PDF

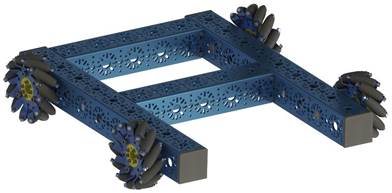

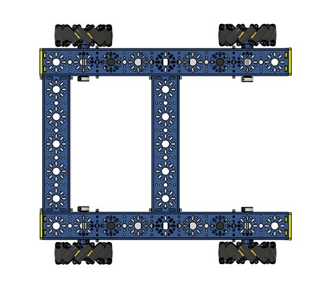

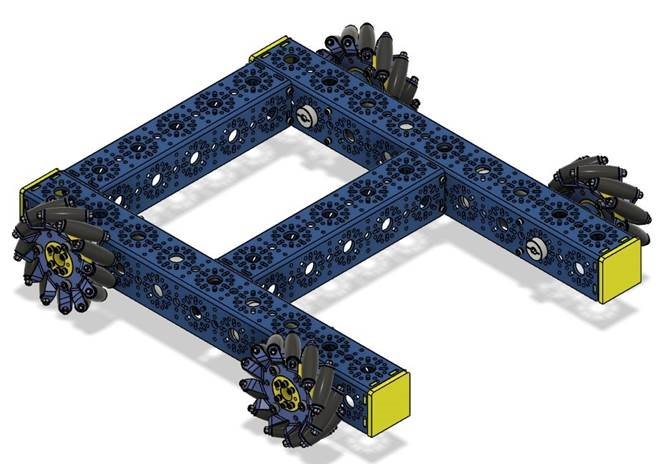

This is an example of what your completed project will look like.

Table of Contents:

• Parts List:

o Structure

o Motion

o Screws, Nuts, Spacers

• Mecanum Drive Base Building Instructions:

o Frame Assembly

o Motion Components

o Final Assembly

o Code

Parts List:

Name | Part # | QTY | |

Structure |

432 mm U-Channel | 76010 | 2 |

|

240 mm U-Channel | 76014 | 2 |

|

End Piece Plate (2 pack) | 76143-2 | 2 |

|

U-Channel Bumper (4 Pack) | 76505-4 | 1 |

|

Rubber Grommet (10 pack) | 76504-10 | 1 |

|

Motion | |

NeveRest Orbital Gearmotor JST-VH-2 | am-3637b | 4 |

|

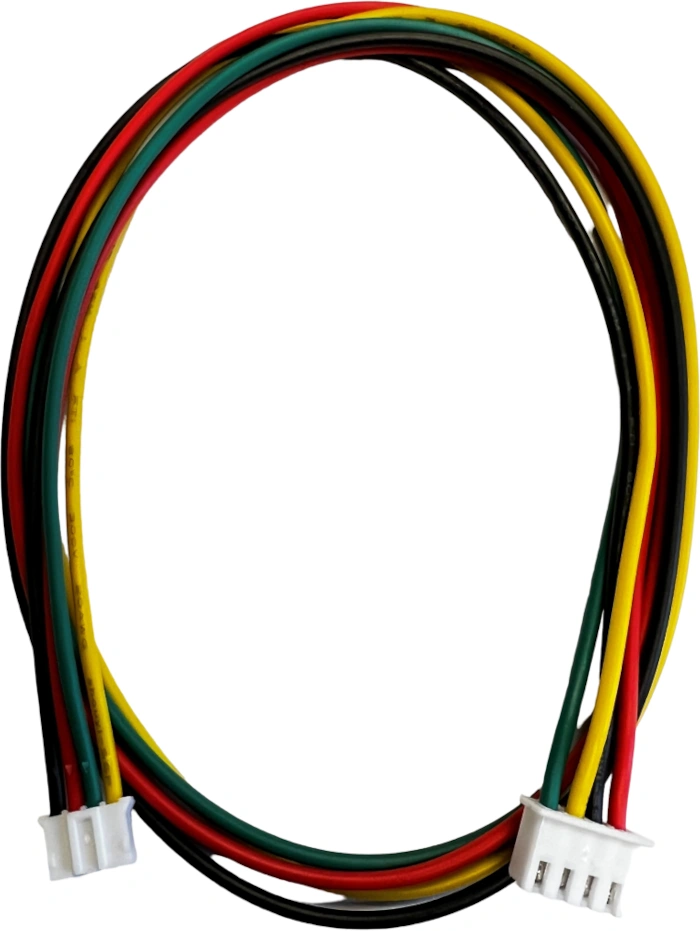

Expansion Hub Encoder Cable | 70197 | 4 |

|

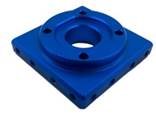

Orbital Mount Plate | 76138 | 4 |

|

30 Tooth Bevel Gear (2 Pack) | 76219-2 | 4 |

|

6mm x 70mm D-Shaft (6 pack) | 76160-6 | 1 |

|

Clamping Shaft Hub | 76280 | 4 |

|

14mm Flange Bearing (12 pack) | 76302-12 | 1 |

|

6mm D-Shape Collar Clamp | 76320 | 4 |

|

100mm Slim Mecanum Wheel Set (Bearing Rollers, 2 left, 2 right) | 76246 | 1 |

|

Hardware | |

M3 x 6mm Socket Head Cap Screw (50 pack) | 76213-50 | 1 |

|

M3 x 10mm Socket Head Cap Screw(100 pack) | 76201-100 | 1 |

|

M3 x 12mm Socket Head Cap Screw (100 pack) | 76202-100 | 1 |

|

M3 x 25mm Socket Head Cap Screw(50 pack) | 76214-50 | 1 |

|

Shaft Spacer Plastic 6mm ID x 10mmOD x 1mm L (24 pack) | 76305-24 | 1 |

|

1mm Thick M3 Screw Spacer (25 pack) | 76309-25 | 2 |  |

Mecanum Drive Base Building Instructions:

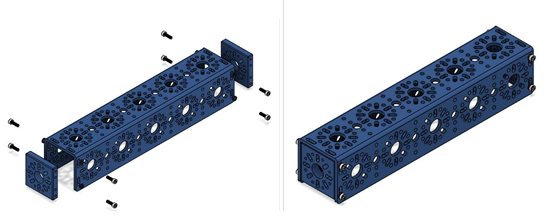

Frame Assembly:

1. Screw the 2 End Piece Plates to each of the 240mm U-Channels using the M3 x 10mm Socket Head Cap Screws with a 1mm Thick M3 Screw Spacer between the screw heads and channels.

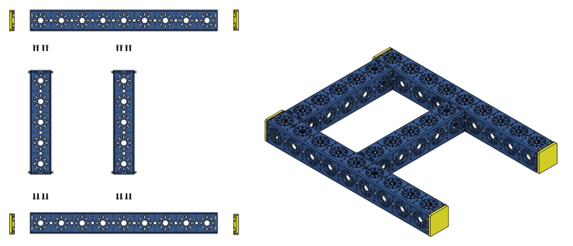

2. Screw the 240mm U-Channels to the 432mm U-Channels using the M3 x 12 mm Socket Head Cap Screws. Then attach 4 U-Channel Bumpers to the ends of each 432mm U-

Channel

a. The 240mm U-Channels should be placed on the end and center of the 432mm

U-Channels (Center being the fifth hole pattern from the end)

Motion Components:

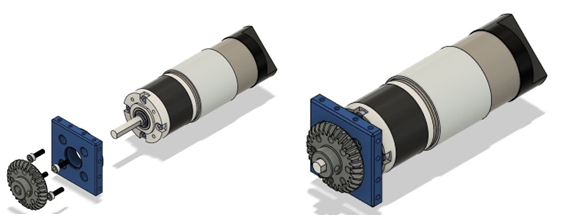

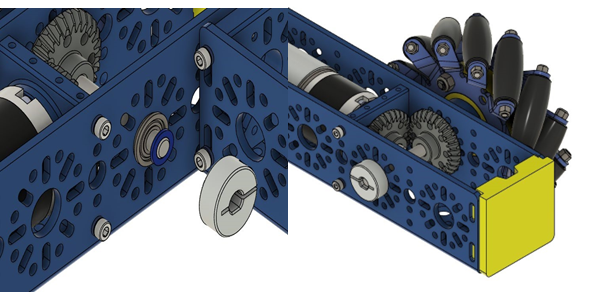

3. Screw the motors onto the Orbital Mount Plate using the M3 x 10mm Socket Head Cap Screws

4. Attach one of the 30 Tooth Bevel Gears to the shaft of the motor and tighten.

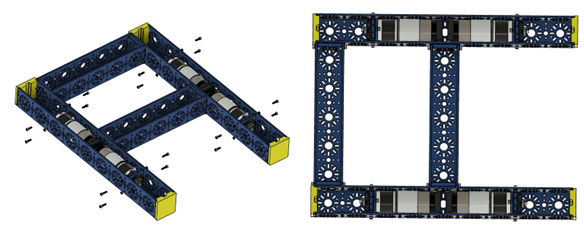

5. Secure the Orbital Mount Plate to the 432mm U-Channels using four M3 x 10mm Socket Head Cap Screws through each plate with a 1mm Thick M3 Screw Spacer between the screw heads and channels.

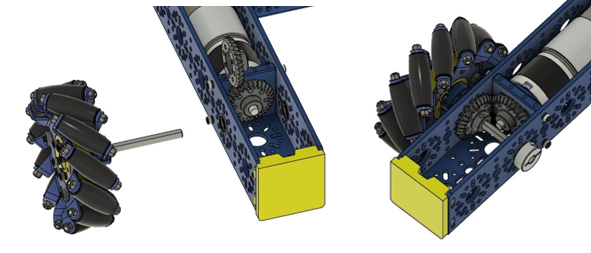

a. Motors should recess in the 432mm U-Channels as shown in the image.

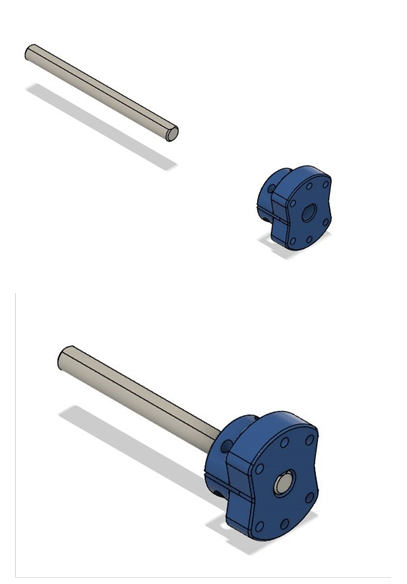

6. Insert the 6mm x 70mm D-Shaft into the Clamping Shaft Hub so it is about flush with the shaft and tighten with the given set screws.

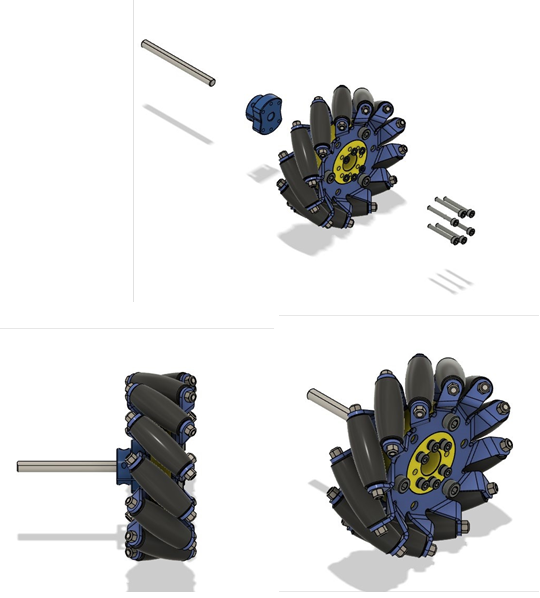

7. Screw the Clamping Shaft Hub to the 100mm Slim Mecanum Wheels using six M3 x 25mm Socket Head Cap Screws for each wheel with a 1mm Thick M3 Screw Spacer between the screw heads and wheel hub.

Final Assembly:

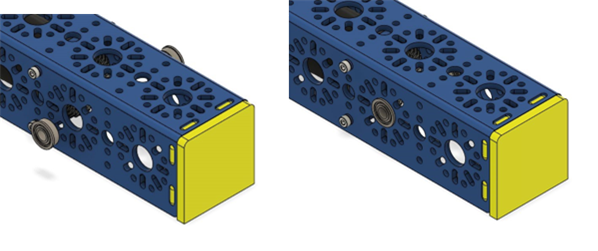

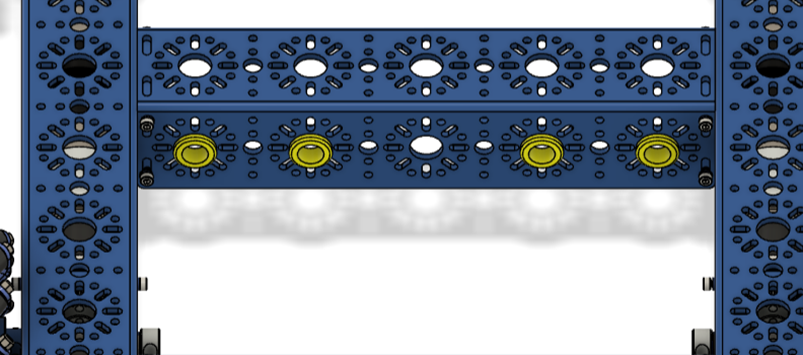

8. Place Flange Bearings onto the 432mm U-Channels where the shafts will be inserted, on the hole pattern adjacent to the Bevel Gear attached to the motor’s shaft.

9. Insert the 70mm D-Shaft through the Flange Bearings and 30 Tooth Bevel Gear on the

432mm U-Channel

a. Before tightening the set screws for the Bevel Gears, make sure the driving gear on the motor shaft and the driven gear on the wheel shaft mesh with one another.

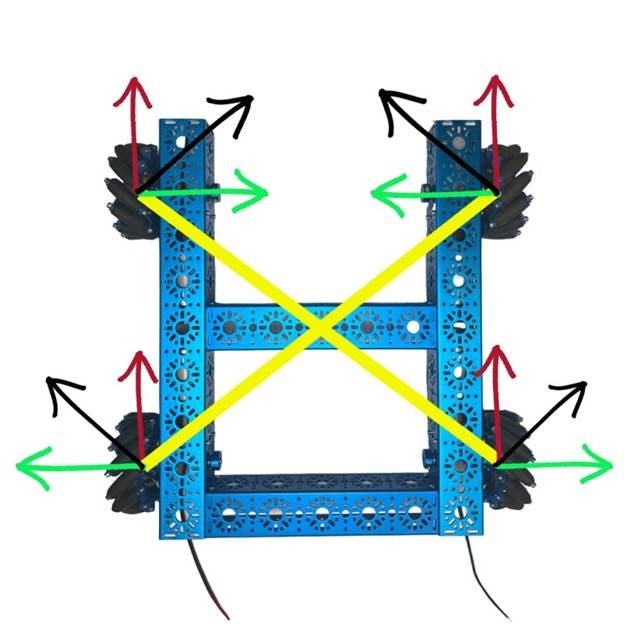

10. The wheels of the drivebase should be oriented like the image below. The rollers should be angled towards the center of the robot in an “X” pattern. This is so the drivebase can drive straight forward and back as well as perform rotations about its center of mass and strafe in any direction. (See pages 13 & 14)

11. Place the 6mm D-Shape Collar Clamp on the end of the 6mm x 70mm D-Shaft and secure it by tightening the clamp with the given set screw with a 1mm Thick Shaft Spacer in between the clamp and bearing.

12. Attach the Rubber Grommets to the 240mm Cross Channel.

Completed Assembly:

IMPORTANT NOTE: “X” Shaped pattern referred to in Step 4 of the Final Assembly. The rollers of each wheel should be pointed inward towards the wheel diagonal to it. (Back Left Wheel pointing towards the Front Right Wheel, and Back Right Wheel pointing towards the Front Left Wheel)

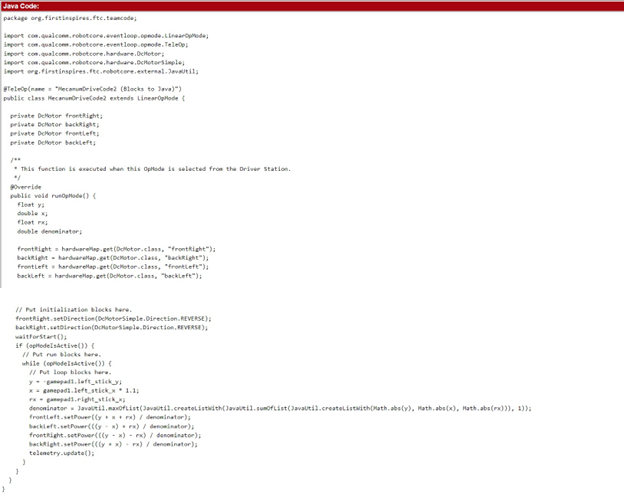

Code for FTC (Onbot Java):

Below is the code for the FTC Drive Base Kit – v2 in Onbot Java for FTC. The variables “x”, ‘y”, and “rx” represent the 3 axes of movement the mecanum drivebase. The left stick controls x and y axis movement (forward, backward, and strafing left to right). The denominator variable is the absolute value of the largest motor power or 1. This is to maintain the power ratio between -1 and 1.