Training Models

Industrial Simulation and Training Models

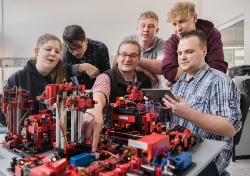

The line of fischertechnik simulation models are designed to provide a compact, engaging, and hands-on method for teaching and demonstrating high end automated systems. The line consists of a series of pre-assembled, small scale models, which are designed to replicate—in appearance and function—various automated/robotic machines and systems commonly used in commercial manufacturing.

These models are ideal for teaching automated systems and PLC programming and control in high schools, CTE programs, college labs, vo-tech schools, and industrial training classes.

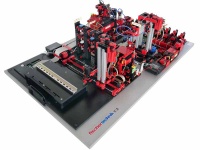

fischertechnik Training Factory Industry 4.0 24V with PLC connection board

Industry 4.0 applications and process flows as a modular training and simulation model

Advantages:

- Including PLC connection board and ready wiring on model and PLC side

- Enables in-depth learning through haptic grasping on a realistic production image

- Digital traceability through NFC/RFID, remote monitoring via camera, sensory applications

- Integrated cloud connection with dashboard, control via smart devices, own cloud and dashboard can be integrated, Raspberry Pi 4 with Node-RED interface

- Communication via OPC/UA and MQTT

The fischertechnik learning environment is used for learning and understanding industry 4.0 applications in vocational school and training and for use in research, teaching and development at universities, in companies and IT departments. The simulation depicts the ordering process, the production process, and the delivery process in digitized and networked process steps.

Training Factory Industry 4.0 in 24v with PLC S7-1500 - Education Version

Industry 4.0 applications and process flows as a modular training and simulation model

Advantages:

- Including PLC Siemens S7-1500, basic program and finished cabling

- Enables in-depth learning through tactile understanding of a realistic production image

- Digital traceability through NFC/RFID, remote monitoring via camera, sensory applications

- Integrated cloud connection with dashboard, control via smart devices, own cloud and dashboard can be integrated, Raspberry Pi 4 with Node-RED interface; Communication via OPC/UA and MQTT

- Dimensions of the model including base plate: 114 x 74 x 34 cm

The fischertechnik learning environment is used for learning and understanding industry 4.0 applications in vocational school and training and for use in research, teaching and development at universities, in companies and IT departments. The simulation depicts the ordering process, the production process, and the delivery process in digitized and networked process steps.

Storage and Transport Case

A storage and transport case for safe storage and transport of fischertechnik Factory Simulation and Training Factory Industry 4.0 models.

Advantages:

- A practical custom case for safe storage and transport of fischertechnik factory models

- Insert once - done! The lower part of the factory is fully functional, only the hood has to be moved.

- Inside lined with soft foam padding

- 3 inside zipper pockets for stowing accessories

- 4 tiltable carrying handles

Quality Control w/AI - 9V version

The use of artificial intelligence in industry, education and research is becoming more and more important. The Quality Control with AI System model from fischertechnik is ideal for visualising this complex subject in a hands-on way since it creates a sustainable learning experience by linking theory and practice.

Agile Production Simulation 24V

The fischertechnik Agile Production Simulation (APS) 24V with S7-1200 PLCs is designed as an ideal training model tailored for Higher Education and professional Industrial training applications. Consists of individual modules such as incoming and outgoing goods, high-bay warehouse, milling station, drilling station, and quality assurance with AI. A driverless transport system flexibly transports workpieces between the individual stations and ensures a flexible production process that can be adapted to customer requirements.

Download Brochure here

6-Axis Robot 9V

Storage and Transport Case for Agile Production Simulation

The storage and transport case for fischertechnik Agile Production Simulation set.

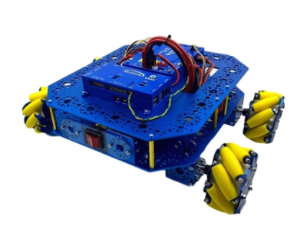

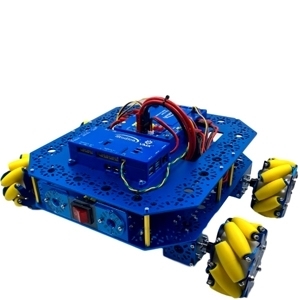

APS ADD ON: Automated Guided Vehicle

Ideal add-on for expanding the capabilities of the Agile Production Simualtion Model

The APS Add On: Automated guided vehicle system extends the Agile Production Simulation (APS) with an additional automated guided vehicle system (AGV). This is responsible for intralogistics within APS and enables agile and flexible processes. The additional AGV significantly increases the possibilities of intralogistics. Parallelization and prioritization in the production workflow can be planned, tested and experienced. At the same time, the complexity of logistics processes increases.