Training Models

Industrial Simulation and Training Models

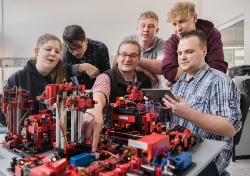

The line of fischertechnik simulation models are designed to provide a compact, engaging, and hands-on method for teaching and demonstrating high end automated systems. The line consists of a series of pre-assembled, small scale models, which are designed to replicate—in appearance and function—various automated/robotic machines and systems commonly used in commercial manufacturing.

These models are ideal for teaching automated systems and PLC programming and control in high schools, CTE programs, college labs, vo-tech schools, and industrial training classes.

fischertechnik Conveyor Belt 24V

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Conveyor Belt 9V

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

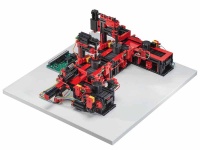

fischertechnik Factory Simulation 24V

The fischertechnik Factory Simulation model combines four models --Vacuum Gripper Robot, Automated High Bay Warehouse, Multi-Processing Station with Oven, and the Sorting Line with Color Detection--into one self-contained material cycle.

Workpieces are retrieved from the Automated High Bay Warehouse using the Vacuum Gripper Robot, and then moved to the Multi-Processing Station with Oven. After the work-piece has been processed by this machine, it is then sorted by color in the Sorting Line with Color Detection, before being again moved by the Vacuum Gripper Robot to the Automated High Bay Warehouse for storage. This fully assembled factory simulation training model is ideal for use with PLCs (Programable Logic Controllers) and PLC programming software.

fischertechnik Indexed line with 2 Machining Stations 24V

U-shaped conveyor line. Features a milling and a drilling station, and four conveyor belt sections. Fully assembled training model for use with PLC (Programmable Logic Controllers) and PLC programming software.

fischertechnik Multi-Processing Station with Oven 24V

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Punching Machine with Conveyor Belt 9V

Conveyor belt with two light barriers, one machining station, and one workpiece. Designed to simulate the movement and punching of workpieces on an automated line. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

fischertechnik Sorting Line with Color Detection 24V

System for detecting workpieces of different colors and sorting them via a conveyor belt into three different storage bins. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Sorting Line with Color Detection 9V

System for detecting workpieces of different colors and sorting them via a conveyor belt into three different storage bins. Fully assembled training model, wired to pre-programmed fischertechnik ROBOTICS TXT Controller.