Industrial Simulation

Industrial Simulation & Training Models

fischertechnik industrial simulation and training models are designed to provide a compact, engaging method for teaching and demonstrating high-end automated systems. These pre-assembled, small-scale training models are ideal for manufacturing simulation, industrial automation simulation, factory simulation, and plant simulation. Explore Industry 4.0, IoT, PLC programming, and more. These training models can replicate a variety of automated and robotic machines. Models including a PLC Trainer, Training Industry Factory 4.0, Factory Simulation and Agile Production Simulation are available.

Download our fischertechnik Industry Solutions Guide 2025

Please contact us at info@studica.com for a consultation with an Account Manager.

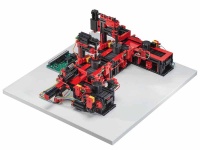

Agile Production Simulation 24V

The fischertechnik Agile Production Simulation (APS) 24V with S7-1200 PLCs is designed as an ideal training model tailored for Higher Education and professional Industrial training applications. Consists of individual modules such as incoming and outgoing goods, high-bay warehouse, milling station, drilling station, and quality assurance with AI. A driverless transport system flexibly transports workpieces between the individual stations and ensures a flexible production process that can be adapted to customer requirements.

Download Brochure here

Storage and Transport Case

A storage and transport case for safe storage and transport of fischertechnik Factory Simulation and Training Factory Industry 4.0 models.

Advantages:

- A practical custom case for safe storage and transport of fischertechnik factory models

- Insert once - done! The lower part of the factory is fully functional, only the hood has to be moved.

- Inside lined with soft foam padding

- 3 inside zipper pockets for stowing accessories

- 4 tiltable carrying handles

fischertechnik Conveyor Belt 24V

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Conveyor Belt 9V

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

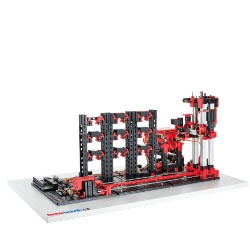

fischertechnik Factory Simulation 24V

The fischertechnik Factory Simulation model combines four models --Vacuum Gripper Robot, Automated High Bay Warehouse, Multi-Processing Station with Oven, and the Sorting Line with Color Detection--into one self-contained material cycle.

Workpieces are retrieved from the Automated High Bay Warehouse using the Vacuum Gripper Robot, and then moved to the Multi-Processing Station with Oven. After the work-piece has been processed by this machine, it is then sorted by color in the Sorting Line with Color Detection, before being again moved by the Vacuum Gripper Robot to the Automated High Bay Warehouse for storage. This fully assembled factory simulation training model is ideal for use with PLCs (Programable Logic Controllers) and PLC programming software.

fischertechnik Indexed line with 2 Machining Stations 24V

U-shaped conveyor line. Features a milling and a drilling station, and four conveyor belt sections. Fully assembled training model for use with PLC (Programmable Logic Controllers) and PLC programming software.

fischertechnik Indexed Line with 2 Machining Stations 9V

This is an older version of the current #51664 model, which was manufactured circa 2008.. It is a 9V version of the model, which is controlled by the fischertechnik ROBO Interface.

Please note that this model does NOT use any of the current fischertechnik contrrollers or controil software All sales are final.

fischertechnik Multi-Processing Station with Oven 24V

Furnace with pneumatic sliding door. Downstream processing station with pneumatic transfer unit including vacuum gripper, cutter with rotary table, and conveyor belt. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.