Education

Education Solutions

fischertechnik Education is dedicated to supporting STEM education. They offer hands-on solutions for learners of all ages, from kindergarten and elementary, through middle & high school, right on up to college & university, and even industry. Students are able to develop a deep understanding of how devices and mechanisms work.

CLASS SET Electrical Control

How does the light in the stairwell come on? Why does it go on at the bottom and off at the top? These and many other questions about electrical circuits are taught in an engaging and kid-friendly way using our Class Set Electrical Control with nine models and 25 experiments. The models can be easily built in class and directly integrated with the ready-made tasks and solutions.

- Main topics Electrical circuits, series-parallel connection, motorcontrol

- Includes downloadable teaching and activity material (free download)

- Set includes. 2x mini pushbuttons, LED, motor, holder for 9V battery (battery not included)

CLASS SET Gears

How does a bevel gear, a belt gear or a rack and pinion gear work? What happens when the transmission ratio changes? Young students age 7 and up can investigate these and many other questions using 15 models and twelve experiments. The models can be set up quickly and easily in the classroom and can be used optimally with the help of the ready-made tasks and solutions.

- Main topics simple gear types/ratios, directions of rotation, types of motion of gears

- Includes downloadable teaching and activity materal (free download)

- Set includes gears, bevel gears, rack, belt, chain, axles, building blocks, base plate 120x60 mm.

- Ideal complement: STEM Gear Tech

CLASS SET Optics

Explore optical phenomena, and experiment with light in class! Explore penumbra and umbra, discover many exciting things with a magnifying glass or determine the time with a sundial. These and many other exciting topics can be taught in an engaging and hands-on manner using the CLASS SET Optics. In addition to the six models, which can be built quickly and are therefore easy to teach, the kit offers six exciting experiments.

- Main topics optical phenomena / light experiments, magnification, reflection, light & shadow

- Includes downloadable teaching and activity material (free download)

- Set includes lens f=25mm, lens f=80mm, mirror, 2x LED, holder for 9V battery (battery not included)

CLASS SET Solar Energy

Renewable energies are becoming increasingly important to our future. The CLASS SET Solar Energy is the perfect method for introducing young students to this vitally important topic. With three quickly assembled models, the basics of solar energy can be taught in class using ten ready-made tasks, including solutions, with lots of fun and exciting insights.

- Main topics energy generation from renewable solar energy, series-parallel connection

- Includes downloadable teaching and activity material (free download)

- Set includes 2 solar modules, 1V solar motor, mini push-button

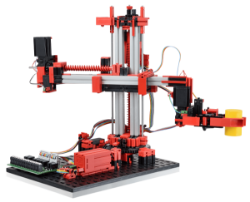

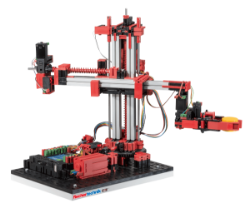

fischertechnik 3-D Robot 24V (3 axis)

3-axis robot with gripping forceps. Robot quickly and precisely positions workpieces in three -dimensional space. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik 3-D Robot 9V (3 axis)

3-axis robot with gripping forceps. Robot quickly and precisely positions workpieces in three -dimensional space. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

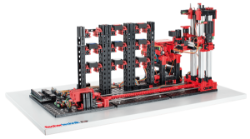

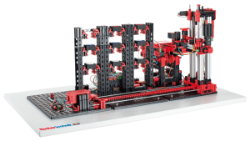

fischertechnik Automated High Bay Warehouse 24V

Transfer station with conveyor belt, with shelf stacker for storing and retrieving special workpiece carriers, and 9 storage spots. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Automated High Bay Warehouse 9V

Transfer station with conveyor belt, with shelf stacker for storing and retrieving special workpiece carriers, and 9 storage spots. Fully assembled training model, wired to pre-programmed fischertechnik ROBOTICS TXT Controller.

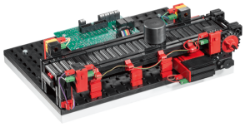

fischertechnik Conveyor Belt 24V

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model for use with PLC (Programable Logic Controllers) and PLC programming software.

fischertechnik Conveyor Belt 9V

Model consists of a transport belt with a length of 275 mm. used to transport workpieces with a diameter of up to 29mm. Multiple conveyors can easily be connected to increase the length of transport as desired. Fully assembled training model, wired to one pre-programmed fischertechnik ROBOTICS TXT Controller.

fischertechnik Creative Box Basic

The Creative Box Basic allows students to unleash their creativity. Equipped with a large assortment of building blocks, angle brackets, building plates and various other static elements, this set is the perfect enhancement to your current fischertechnik parts collection. The Creative Box Basic is great for freestyle building, reconstructing an existing theme or model, or expanding upon any existing FT projects.

fischertechnik Creative Box Mechanics

The fischertechnik Creative Box Mechanics is the perfect addition to your favorite technically themed FT sets and projects. The collection of gear wheels, pinions, axles, and other components allow students to construct simple mechanical models such as a worm drive, a chain transmission, or a winch. The hands-on building of these models makes it easy for students to recognize and understand how they function, as well as promoting constructive thinking.

fischertechnik Designer Software

NEW VERSION--The ideal software to plan, develop, and implement fischertechnik models. Easy to navigate, with a huge range of functions available. Perfect for schools, universities, training, or for anyone who needs to visualize technical processes using the fischertechnik system.

fischertechnik Education Accu Set - 110V

fischertechnik Accu Set provides fast, reliable charging of your rechargeable NiMH battery (included). This high-powered NiMH Accu Pack also features a microcontroller to protect from overcharging. With this short-circuit protection, the charger is able to recharge your battery in two hours - at the most (8.4V, 1500mAh)! Keep your fischertechnik designs moving with the fischertechnik Accu Set.

fischertechnik Education Box 1000

fischertechnik Box 1000 secures and stores up to 42 fischertechnik parts. This item comes with 8 sorting boxes and 32 sorting paritions. The cover included with the Box 1000 can also serve as a big building board - measuring 390 x 270 mm. Keep your fischertechnik components organized with this practical storage system.

fischertechnik Education Hydraulics

Fundamentals of Hydraulics

School and university students learn about hydraulic content with this realistic educational construction kit. This new set offers hands-on technology for learning about the transfer of force using liquids. Five different models illustrate how signals and forces can be transferred with liquid media. Students can build a simple functional demonstration model, an excavator, and three other models. Combined with the accompanying educational materials, the set helps to provide a solid overview on the topic of hydraulics. The downloadable teaching and activity materials are provided free of charge on the eLearning Portal to support teachers in preparing for and designing their curricula.

Includes instructional activity information (free download)

Components include 4 control cylinders, and 4 working cylinders

Contains 475 parts for building 5 different models.